The footwear brand AKU invited a few of the Trekitt team to test out their boots and explore their factory. See how it went and enjoy our journey- four days in Dolomites with Aku.

“The history of AKU begins in a shoemaker’s workshop in a district of Montebelluna. The small Venetian town that for over a century has built and spread the myth of Italian sports footwear all over the world.”

Four days in Dolomites

When you’re asked if you’d like to go to the Dolomites for free, you just say yes. A couple of plane tickets and an itinerary followed shortly after and that was that.

It’s 6:30am and we’ve just arrived at the airport. I’m joined by Debbie, Trekitt’s Retail Supervisor. Luckily she knows how to navigate airports efficiently. I’m completely lost in what seems to be a gated sea of chaos and stress. A fairly uneventful check-in later and we’re on our flight to Marco Polo, Venice. It seemed the early start was slightly unnecessary as our transfer to the hotel wasn’t until late afternoon. However, since the town is only a short bus journey away from the airport, we used this free time to indulge in some Italian-ness—coffee and pizza. The waterways are quiet, the cafes filled with life and the skies clear. Visiting again with more time is absolutely on the bucket list. I feel like we only scratched the surface.

Day 1: Shoe pick up and adventure kickoff

Once picked up, we were taken to AKU’s hometown of Montebelluna. We collected the boots we’d be using over the next few days. We were followed by a winding trip through the jagged mountains to our hotel in Val Canali. Sitting behind a layer of glass as you pass miles and miles of seemingly perfect landscape was a bit like watching the waiter walk to another table with the same food you’ve just ordered—la sofferenza. The following day more than made up for this though.

Day 2: Aku Boots in Dolomites- first impression

Day two on the itinerary indicated a day in the mountains. It’s something we’d all been craving since arriving. We downed a big breakfast of yoghurt, fruit, toast and of course, coffee. We laced up our new boots for their maiden voyage and off we went. The ones in question were AKU’s Slope GTX, a boot we’ve stocked for quite a while ( pictured below). They fitted almost perfectly for the majority of the group and were comfortable straight from the box. Our hosts assured us there would be a location to fill up our bottles en route, so our packs were fairly light.

Aku neckware

The route took us along the valley floor for a short path into the woodland that sits a few hundred metres up. At this point I was fully expecting the boots to slip on my heel slightly (feet like matchsticks, very used to it). I was surprised as they were absolutely fine. The path winds higher passing the occasional deer and crossing logging paths that are used to construct the local ski lodges before opening up to an unobstructed view of the snow-scattered summits. As well as the boots, AKU kindly donated some neckwear for us. Despite being around 0°C in the shade, they were a saviour when the sun came out as a bit of UV protection.

Local Cheese and wine fest: a flavorful day to savor

At some point the previous day, our host, Vittorio, assured us that he knew of a local shop that sold the best cheese we’d ever had. Little did we know he’d packed half a wheel of it, along with a bottle of local wine. I’ll be honest. I’m not a huge fan of cheese so I left it to those who would actually enjoy it. However, I was told it was pretty damn good.

Four days in Dolomites- the best lunch stop

A few hours later we arrived at the highest point on our walk which doubled up as our lunch spot. The best lunch spot I’ve ever experienced, I should add. We were provided sandwiches, salads, cake and various other snacks that were as exceptional as the view. Despite my very limited experience of Italy and its cultures, I’ve noticed they tend to take a lot more time to experience things than we do. Lunch isn’t simply a matter of shovelling in a load of food and moving on. It is rather a chance to stop, rest, take in where you are and relax for a while. There were frequent stops along the way for no particular reason and a set time may have half an hour leeway either side for socialising or making coffee.

Drinking from the river

The rest of the route included descending back to the valley floor. We were filling up our bottles from the fresh running river, taking photos and, in my case, rummaging around my pack for remaining snacks. We made it back to our accommodation in time to watch a film AKU had prepared featuring our mountain guide for the day, Peter Moser.

Four days in Dolomites- Day 3

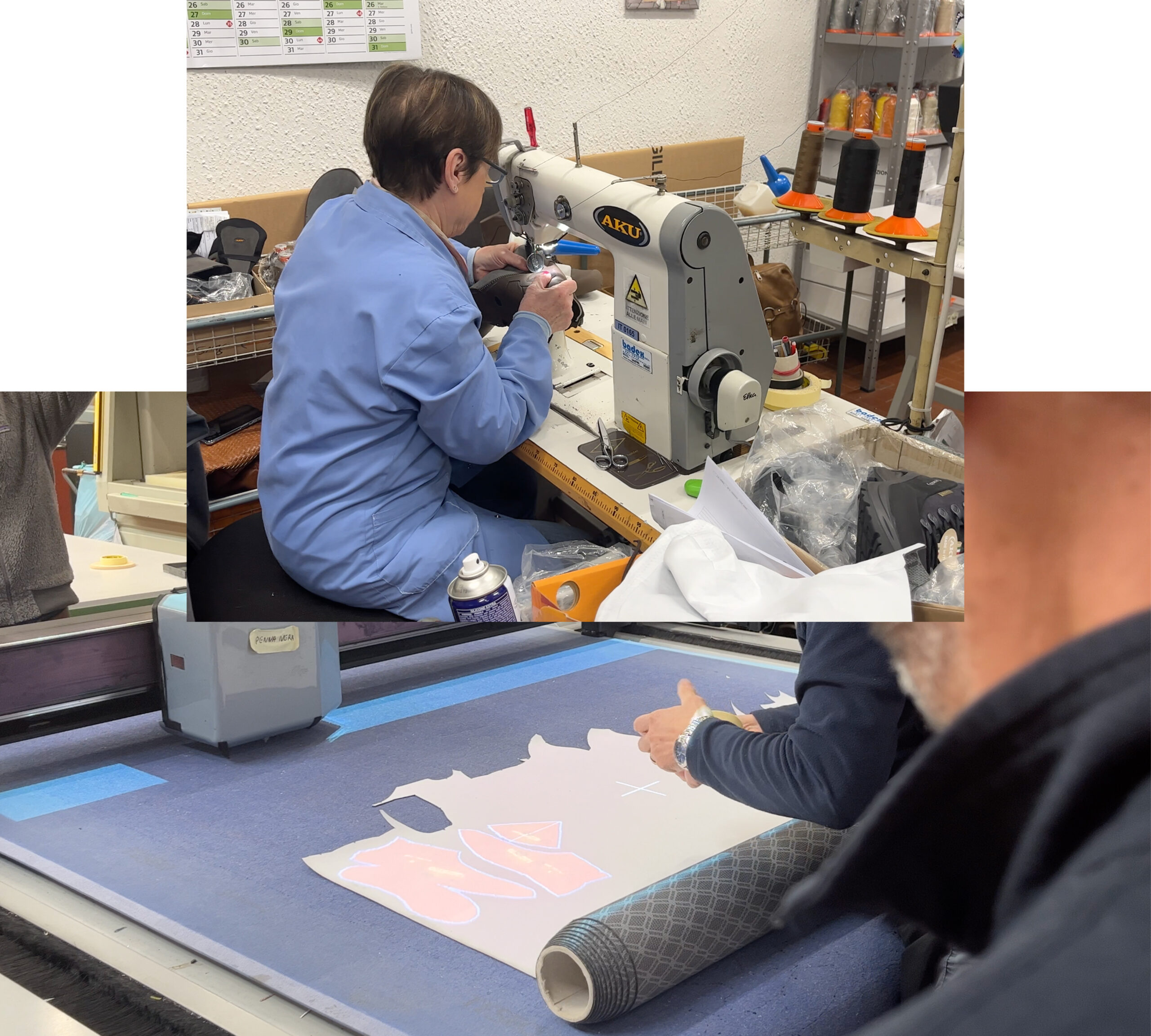

AKU had arranged a factory tour for the group back in Montebelluna. We had a chance to see how the boots are made, the processes they use, meet some of the staff and generally get to grips with how much effort is actually put into making a seemingly simple object (spoiler, they’re not simple).

I should add here that not all AKU’s boots are made here. It’s mainly the more ‘specialist’ models while the rest are made in various other factories around the world. Of the boots that are made here, 90% of the raw materials are sourced from Italy, while smaller items such as the laces are made just 3km away in the same town. In the particular boot we were using, all the upper materials are recycled, the Gore-Tex membrane is laminated with 99% recycled yarns, the laces are recycled and the midsole contains 20% recycled materials.

Aku footwear factory tour

There are various tests that are carried out in the factory before being constructed into a piece of footwear. The strange white bag attached to the machine below is the Gore- Tex membrane. It provides the waterproofing in AKU’s (and most other companies’) footwear. It’s clamped shut around a small tube, inflated, then dunked into the water. If it isn’t waterproof, you’ll see bubbles escaping and it doesn’t make it into a boot— this is done for every boot that leaves the factory. If, for a rare reason a boot arrives with you, the customer, and is thought to be leaking, there’s a machine across the room that can test this and resolve the issue accordingly. Clever stuff.

A world beyond scalpels and manpower

Historically, someone with a scalpel would look at a piece of material, have another look at the stencils needed to be cut from it and work out how many pieces they could remove. Now you’ve still got the person, but instead they line up a projection of the pieces and move them automatically into position. This is quicker and wastes far less material than before—a useful piece of technology that benefits everyone in some way.

Footwear is still stitched by hand in the Montebelluna factory, making no two pair of boots exactly the same. Many of the staff have been working in this location for upwards of twenty years and it shows. I imagine if I tried stitching a boot together.I would end up looking like a four-year-old’s art project. The one which you stick on a shelf in the kitchen despite not knowing what it’s supposed to be.

Four days in Dolomites with Aku- final word

The remainder of the day consisted of having a tour of AKU’s store just next to their factory. I’d highly recommend visiting if you’re in the area and pizza at a local restaurant. The last day of the trip was entirely taken up by trave;. I won’t subject you to that, so I’ll end this blog here. Big thanks to everyone involved for a well- organised and highly enjoyable trip. If you’re interested in any AKU footwear then we stock a bunch of it here.

Leave a Reply