Big news. Gore-Tex® is changing.

Why, you ask? For the environment. It’s as simple as that. However, first, let’s go all the way back to the beginning. Let’s delve a little deeper into the brand’s history, what they do, and why this change to their products is so important.

The History of Gore-Tex®

Gore-Tex® was founded in 1958 by Wilbert L Gore and Genevieve Gore. It all began in the basement of their home in Newark, Delaware. At the time, Bill worked as a chemical engineer. He quit his job in pursuit of his belief in the unexploited power of PTFE (polymer polytetrafluoroethylene). In 1969, the family business struck a turning point that would change their brand forever. ePTFE (expanded polytetrafluoroethylene), which we’ll explain a little later, was created by Wilbert’s son, Bob Gore, during this year. It was created by stretching the original PTFE under particular conditions, resulting in a super strong, microporous material with fantastic performance features. Following this discovery, the company really began to take shape. ePTFE was patented, and the Gore family began revolutionising the outdoor industry (along with others) under the Gore-Tex® label.

The first Gore-Tex® products

The first products made with ePTFE by the brand were actually plumber’s tape and miniaturised coaxial cable. Then, in 1966, NASA launched its first crewless mission to the moon with a lunar soft lander, named the Surveyor 1. NASA built this craft with Gore-Tex® cables. Three years later, Apollo 11 landed on the moon carrying three astronauts with the familiar names of Neil Armstrong, Buzz Aldrin and Michael Collins. Part of this mission incorporated the installation of seismographic equipment connected to the lunar lander, using more of Gore’s cables. These cables were ideal, as they offered the durability and performance required in such unknown environments.

The beginning of wearable Gore-Tex®

By 1976, Gore-Tex® began to fit its membranes into jackets, receiving its first commercial orders for their fabrics. This is when the brand began to see outdoor enthusiasts wear their products in nature. At the time, this was the first and only breathable, waterproof and windproof fabric on the market. In 1979, Gore-Seam® was introduced.

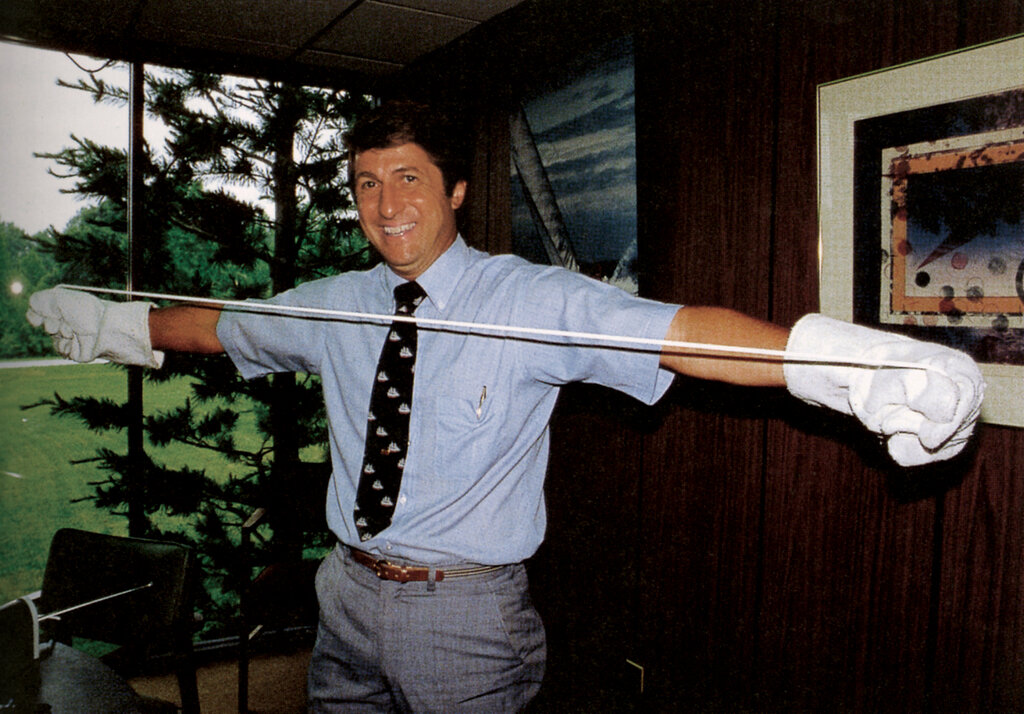

Gore-Seam® is waterproof seam taping that is added to each seam on the inside of a jacket. It helps to increase a product’s waterproof (in this case, for explanatory purposes, a jacket) capabilities, offering improved protection from the elements. The year following then saw Gore-Tex® introduce a new two-layer fabric, and a waterproof, windproof and breathable insert that could be used in gloves. Once again, these new products revolutionized essential products of the outdoor and working industries. In 1981, Gore even started to create spacesuits for further NASA projects.

Innovation continued throughout the 80’s, when Gore-Tex® introduced their Gore-Tex® Z-liner and the first Gore-Tex® fabric bootie for footwear. Towards the end of the decade, Gore-Tex® introduced their Guaranteed To Keep You Dry® promise, which still applies to their products today.

Antarctica and new innovations

In 1990, an international team of adventurers headed on expedition to Antarctica wearing Gore-Tex® outerwear; one participant even credited the materials for saving his life. Eight years later, Gore-Tex® also introduced the original Gore-Tex Paclite® technology, providing customers with lighter, more packable options. After the millennium, Gore-Tex® continued to create and release new innovations, including Gore-Tex XCR® Gloves in 2003, Gore-Tex® Pro in 2006, Gore-Tex® Active and Gore-Tex Surround Footwear® in 2010, ShakeDry™ in 2016, Gore-Tex® Invisible Fit in 2017 and Gore-Tex Infinium™ in 2018. Even today, the brand continuously strives to create new technologies that will continue to revolutionize the industry – it’ll be exciting to see what they produce in the future.

How Is Gore-Tex® Constructed?

There are many different Gore-Tex® products on offer, that use varied types of construction.

Three-layer Gore-Tex®

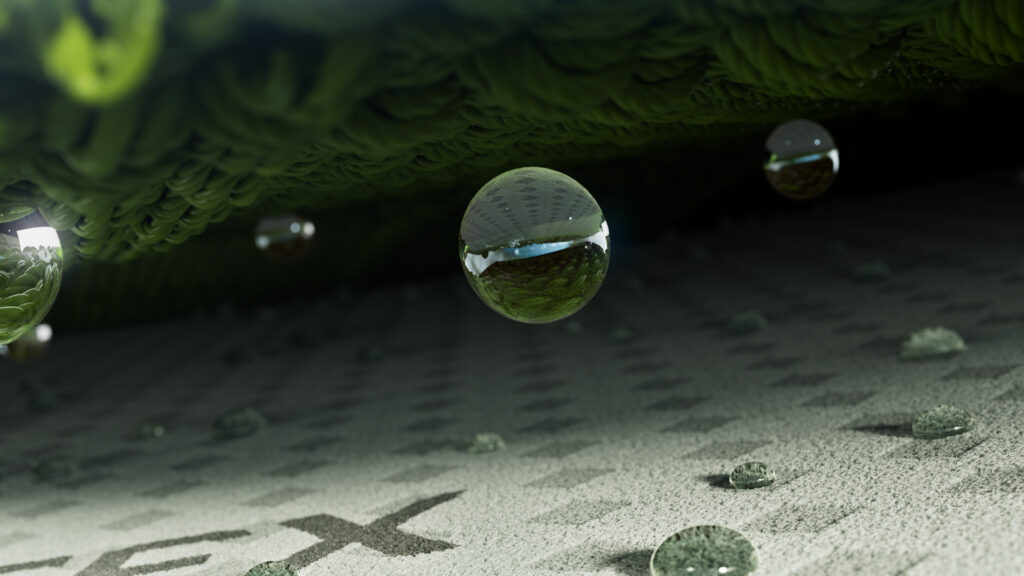

The most common structure of a waterproof Gore-Tex® material uses three layers, including a waterproof membrane which is sandwiched between the face (outer) and backer fabrics. The face fabric is also treated with a DWR (durable water repellent), forcing the water to bead off the material. When a membrane and support material are bonded together, this forms a laminate. Out of the three primary layers of textiles, not including DWR, the membrane is the component being changed this year.

The importance of using the right material

The tougher the face fabric is (the higher the denier), the less breathable your jacket will be. The backer (lining) can also define how flexible and durable the end product turns out, so making the right fabric choices is essential when designing a product for specific purposes. This is where Gore® stand-out, as they can be incredibly picky when it comes to combining their membranes with particular face or backer fabrics – they don’t let just anyone choose any material combination they want.

Which materials are used with the ePE membrane?

With the updated ePE membrane, these materials will be primarily recycled, solution-dyed or undyed (depending on the laminate selection) to further reduce environmental impact and enhance the laminates suitability to their intended end-uses. This ensures maximum performance and functionality for each product. However, overall, it is the waterproof membrane that still dictates how waterproof a product is.

In ePE-based products, when recycled face or backer materials are used, you may notice the percentage of recycled content varies. This is according to the choice of the laminate used in that particular product. Solution-dyed textiles use fewer chemicals compared to regular dye, as well as less water, emitting less carbon, too. Solution-dyeing also increases overall colour fastness (resistance to colour fading/running).

The Sciency Stuff

So, as you now know, Gore-Tex® has used a chemical called ePTFE in its products for decades. ePTFE is a fluorocarbon with unique chemical and physical properties that can withstand exposure to harsh substances and maintain performance in extreme environments. This chemical is what makes Gore-Tex® so robust, and still allows membranes to be protective whilst remaining lightweight and breathable.

The environmental impact of ePTFE

However, unfortunately ePTFE isn’t all sunshine and rainbows. It contains chemical compounds called C6, C8 and sometimes C12 (depending on the type of waterproof membrane), which are actually classed as ‘forever chemicals’. The outdoor industry is slowly trying to eliminate these chemicals from its products, as they permanently stay in the environment once disposed of, continuing to cause damage to our ecosystems for years after use. The chemicals themselves don’t just fall off your jacket as you’re walking up Pen Y Fan, but in the manufacturing process they can enter the water table and remain there forever. They also cause great harm to factory workers involved with using them.

Gore-Tex® goes green

To help combat this issue, Gore-Tex® have slowly been making changes to their products, as part of a sustainability mission launched back in 2017. This year, we’re seeing more of these updated products emerge, switching from an ePTFE membrane to an ePE-based one. This transition cuts out those nasty compounds and replaces them with C0 compounds, which contain no forever chemicals, making them better for our planet’s long-term health. But what does this mean for our waterproofs?

How Does ePE Perform vs ‘Traditional’ Gore-Tex®

Gore-Tex® still assure the same quality and performance with ePE products as their original ones. ePE products may feel lighter, or thinner, but are still durable, waterproof, windproof and breathable enough for adventuring outdoors.

The performance of ePE

The switch to ePE might mean you notice a difference in the performance of your waterproof. It’s important to note that this will not make the performance of your waterproof worse, but it will require you to take a little more care in maintaining your kit when you use it. This is because the ePE membrane won’t wick moisture (sweat) and oils away as effectively for as long. Therefore, it may wet out quicker than the previous ePTFE-based product.

How to prevent your Gore-Tex® gear from ‘wetting out’

If you’re not sure, wetting out means that your jacket (for example) stops beading when water hits the face fabric; those little droplets of rain that usually hit the surface and roll straight off begin to soak into the outer fabric. This is visible when you wear your jacket, so it can be an easy issue to spot. This doesn’t mean the water will begin to soak through, but that your jacket becomes less breathable, and therefore may feel damp on the inside, causing you to think the jacket is failing. When a jacket wets out, this is usually due to the lack of DWR, which can wear off the more you use it.

We stress that this doesn’t mean it won’t perform! But you must maintain your gear to consistently achieve maximum performance. This is where regularly washing your jacket and reapplying a DWR comes in.

The Truth About DWR

Before I delve deeper into how to care for the new Gore-Tex® membrane, I want to address one relative topic – DWR. DWR stands for Durable Water Repellent. All waterproof jackets have these coatings, as well as a waterproof membrane.

Is my Gore-Tex® jacket faulty?

After using your waterproof numerous times, you may notice that your jacket is starting to ‘wet out’. This is (in most cases) not because your jacket is failing or faulty; this is usually because the DWR needs to be reapplied. The jacket itself will remain waterproof, but the lack of remaining DWR can cause your jacket to lose breathability, generating condensation within and making it feel damp.

Changing the narrative

We own up to being one of many businesses who call the process of reapplying the DWR ‘reproofing’. However, technically, this phrase is incorrect, because we aren’t reapplying the waterproof membrane to the jacket, only the DWR. As a result, we are now trying to change the narrative of maintaining and caring for your waterproof gear, and this is where it begins.

How To Care For New Gore-Tex®

The new changes will require us all to keep on top of care and maintenance, meaning washing and reapplying the DWR more regularly. We would recommend doubling the amount of times you would usually wash your shell garments. For example, if you clean and re-repel your jacket twice a year, do it four times a year instead. Unfortunately, we can’t recommend a specific number, as it varies from user to user, depending on how often you use the jacket or even what you use it for.

Use our waterproof wash and care guide to help

So, sounds a little complicated, right? Maybe even a little daunting? If you haven’t done it before, it’s actually a pretty simple process; it can easily be done at home, with products that don’t cost the earth. We stock a variety of care products at Trekitt, including Grangers and Nikwax, which you can shop by clicking here.

You can also watch our YouTube video below for a step-by-step guide on caring for your waterproof.

How does Trekitt see this affecting how we layer up in the future?

As a result of the update, we predict a slight change in the way that we use our shell products. It’s quite common that we see people using their shell garments for not only wet weather protection, but wind protection too. With these new ePE-based products emerging, we could see trends where outdoor enthusiasts begin leaning towards windproof and quick-drying options more frequently, saving their waterproofs for only the really rough conditions.

Breathability, weight and durability

The ePE Gore-Tex® products also have a better breathability rating, meaning you could get away with a warmer midlayer underneath, or wear them for faster-paced activities. ePE products also have a fantastic strength-to-weight ratio, meaning they’re lighter and thinner yet still incredibly robust, and able to withstand abrasion well. This could save you a lot of weight or mean you could get away with taking a smaller backpack, as your ePE jacket will take up less room when packed down.

Our range of ePE-based products

To shop the current, growing range of ePE-based Gore-Tex® products, you can click here.

Contact us

As usual, if you need some further advice or have any questions, our lovely customer service team are on hand to help; send us an email at [email protected] or call us, on 01432 263 335. Alternatively, if you’re local, why not pop into our friendly Hereford Service Centre and have a chat with the team?

Leave a Reply